What Does Corded Electric Mean

Corded electric devices plug directly into a wall outlet and draw continuous power, eliminating battery life limits. They’re designed for uninterrupted operation and often deliver higher, more consistent performance. You simply plug in and go, making them a staple in workshops, kitchens, and anywhere you need reliable electricity.

Corded electric gadgets run on a constant, direct power supply rather than batteries. This design usually translates into stronger output—no worrying about your tool slowing down as a battery drains. You also avoid the ongoing cost of battery replacements or recharges. But the trade-off is tethered movement; cords can limit mobility and create potential trip hazards. Still, for tasks demanding steady power—like drilling, vacuuming, or long cooking sessions—corded devices excel at maintaining robust and predictable performance.

Let’s explore how corded devices compare to cordless ones, their key benefits, cost factors, and essential safety tips.

How Do Corded Electric Devices Differ from Cordless Ones?

Corded devices offer steady power from an outlet, while cordless models rely on rechargeable batteries. This fundamental design difference impacts mobility, runtime, and power output.

Cordless tools free you from outlets but can slow or stop once batteries run low. Corded gear, however, never loses power mid-task, giving you consistent torque or suction as long as you’re plugged in. You don’t worry about battery management or replacements, though you must handle cords that can tangle or limit reach. Your choice hinges on whether continuous performance or maximum mobility is more important.

Choosing between corded and cordless boils down to your workspace, project scope, and personal preference. Corded devices supply unvarying voltage from the outlet, ensuring consistent horsepower or rotational speed. This can be a lifesaver for intense projects like drilling concrete, mixing thick paint, or vacuuming a large living space. You won’t pause to swap or recharge batteries, so workflow remains uninterrupted.

Meanwhile, cordless devices1 shine when you must work far from outlets—like yard chores or roof repairs. They cut the clutter of cords, but you’re tied to battery life, which might be short if you have only one battery pack. Extra packs cost more, but they help maintain continuity. Some cordless tools also weigh extra because of the battery, though advanced lithium-ion technology2 is reducing battery bulk.

Key Differences

- Mobility: Cordless is perfect for overhead tasks or sprawling job sites, whereas corded demands an outlet or an extension cord.

- Runtime: Corded can run indefinitely, while cordless depends on battery charge.

- Performance Fade: Cordless tools might slow as voltage drops; corded maintain peak power until switched off.

Practical Considerations

- If your tasks often exceed battery capacity, frequently recharging can be frustrating. Corded devices remove that concern.

- If your environment is well-equipped with outlets or you don’t mind using a heavy-duty extension cord, corded solutions might fit best.

- If you travel a lot or work in areas without reliable electricity, cordless gear offers unparalleled freedom.

Ultimately, both options have valid uses. By pinpointing where and how you’ll operate, you’ll find the right balance of mobility and reliability for your needs.

What Are the Main Advantages of Using Corded Electric Tools?

Corded tools deliver reliable, steady power, making them favorites for demanding tasks. They’re prized in settings where consistent performance and zero downtime trump portability.

Because they don’t rely on batteries, corded electric tools maintain top performance throughout a job. You won’t deal with reduced speed or torque as power depletes, or pause to recharge. They’re often cheaper than their cordless counterparts, since you’re not paying for batteries or advanced charging systems. Plus, with no battery pack attached, some corded devices are lighter—though you must manage the cord carefully to avoid tangles or trip risks.

Ask any contractor or hobbyist who frequently uses power tools: the consistency of corded devices can be a game-changer. By tapping directly into the grid’s power, corded models deliver the same level of performance at hour one or hour ten. There’s no slump in battery charge that can cause slower cuts or weaker drilling. For tasks like sanding a large surface or continuously blending thick materials, that unwavering stamina can be invaluable.

Uninterrupted Workflow

Whether you’re a professional construction worker or a dedicated home DIYer, downtime kills efficiency. Cordless tools risk forced breaks when the battery dies, unless you keep multiple charged packs on hand. Corded devices sidestep that concern—just ensure your circuit can handle the amperage draw3.

Cost-Efficient Setup

Without the overhead of battery technology, corded devices4 often come at a lower price point for the same power rating. Over time, cordless users might spend extra on spare batteries or replacements once they wear out. With corded, you mostly just watch for cord wear or the occasional extension cable upgrade.

Power Density

Certain tasks, like heavy-duty hammer drilling or high-RPM polishing, demand robust torque. Corded motors can sustain high loads consistently, making them well-suited for extended use. You won’t see the subtle drop-offs that come from cordless battery depletion.

Limitations revolve around cord length and outlet availability. Some workplaces mitigate that by installing multiple outlets or using reel extension cords. If you primarily work in a fixed spot—like a workshop or kitchen—a corded setup usually offers superior performance for the price.

Are Corded Electric Devices More Cost-Effective?

Yes—often they are. You skip battery packs, chargers, and replacements, so corded items can have a lower purchase price and minimal ongoing costs.

Cordless gear requires advanced lithium-ion battery packs, which add significantly to the overall tool price. Over time, those batteries wear down and must be replaced. Corded tools avoid that expense, relying on your standard outlet for uninterrupted power. If you’re working in a consistent space with readily available electricity, the cost advantage is clear. You’ll also likely see stronger motor specs for less money.

When evaluating total cost of ownership, compare not just the sticker price of a corded tool versus its cordless counterpart, but also how and where you’ll use it. Cordless sets frequently require spares or second batteries if you want continuous use. Each battery might cost nearly as much as the tool itself. Conversely, with a corded device, there’s no separate power source to buy or maintain.

Upfront vs. Long-Term

- Initial Purchase: Corded devices typically undercut cordless models by 10–30%.

- Ongoing Expenses: Battery packs degrade and eventually need replacing—every 2–5 years. Meanwhile, cords can last a decade or more with minimal care.

Electricity Usage

While it might seem cordless saves on electricity, you’re still drawing power from the grid to charge batteries. The difference in energy bills is minimal unless you’re powering extremely high-draw tools for extended periods daily. In such heavy-use scenarios, many professionals trust corded gear5 for stable performance anyway.

If mobility isn’t crucial, a corded device often delivers better bang for your buck. It spares you from battery-related hassles6 and overhead, letting you focus on the job at hand.

What Safety Precautions Should I Take with a Corded Electric Device?

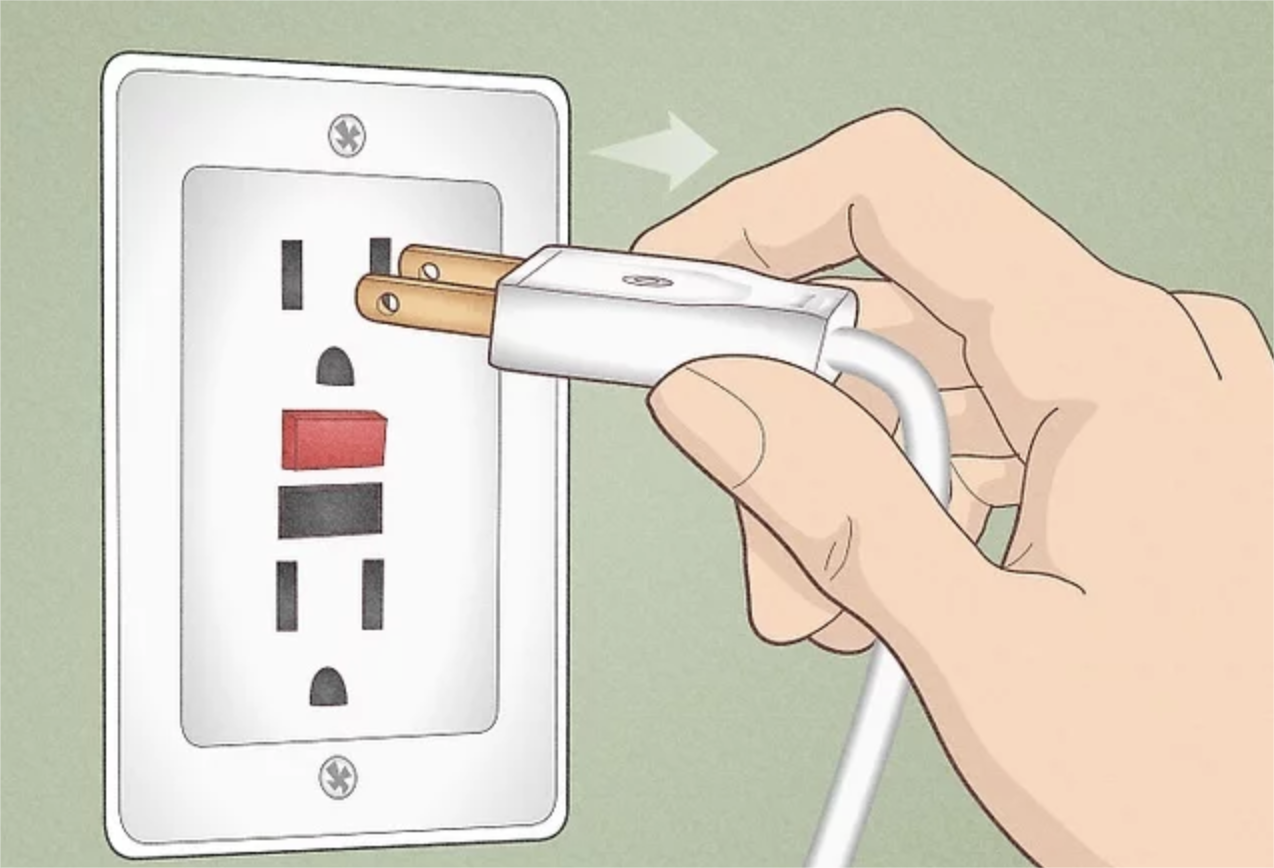

Working with mains electricity requires careful handling. Simple habits—like using the right gauge cord and checking for damage—help you avoid shocks, shorts, or fires.

Ensure your device’s cord is in good shape: no exposed wires, no cracked insulation. Never overload an outlet or extension cord by plugging in high-amperage tools or multiple devices that exceed the circuit’s rating. Keep cords away from water, sharp edges, and heavy foot traffic. If you’re using an extension cord, match it to the device’s power draw—thicker (lower gauge) cords handle heavier loads more safely. If you spot fraying or feel unusual heat, unplug immediately and inspect.

Corded electric devices are largely hassle-free, but a few critical steps ensure your safety:

Cord Inspection

Before each use, quickly check for visible damage—nicks, cuts, or flattened sections from furniture. A seemingly small tear can expose internal wiring to moisture or direct contact, creating shock risks7 or arcing. If damage is found, stop using the cord until it’s repaired or replaced.

Proper Loading

Confirm your device’s amperage draw8 (often printed on a label). If you’re using an extension cord, choose one rated at or above that current. A vacuum cleaner might draw 8–12 amps, so a flimsy 5A cord quickly overheats. Over time, repeated stress can degrade the cable or even lead to melting.

Placement & Trip Hazards

Keep cords along walls or taped down if they cross walkways. This not only prevents tripping but also reduces the chance of accidentally yanking the plug from the outlet. Tidy cord management is especially vital in busy workshops or households with children or pets.

Water & Outdoor Usage

If your project involves moisture, ensure the tool and any extension cord are labeled for outdoor or wet conditions. Standard indoor cords lack the insulation to safely withstand rain or damp surfaces. Also consider using GFCI (Ground Fault Circuit Interrupter) outlets in bathrooms, kitchens, or outdoor areas—these can cut power in milliseconds if a short to ground occurs.

Following these guidelines minimizes shock hazards, prevents equipment damage, and keeps your workspace orderly. A quick pre-check might be all it takes to prevent an accident that could set back your progress or harm someone. When in doubt, consult the device manual for any specialized recommendations or consult an electrician for more complex power needs.

Conclusion

Corded electric devices offer steady, uninterrupted power for demanding tasks and often cost less upfront than cordless alternatives. While the attached cord can limit mobility, careful cord management and proper safety measures keep the experience hassle-free. If you need consistent performance without the hassle of batteries, corded electric is a reliable choice.

-

Discover how cordless devices offer flexibility and convenience for tasks far from power outlets, enhancing mobility. ↩

-

Learn about the advancements in lithium-ion technology that reduce battery bulk and enhance the performance of cordless devices. ↩

-

Learn how to safely use corded tools by ensuring your circuit can handle their power requirements, preventing potential hazards. ↩

-

Explore why corded devices might be the better choice for continuous, high-power tasks without the worry of battery depletion. ↩

-

Explore why professionals trust corded gear for stable performance, especially in heavy-use scenarios, to make informed decisions on your tools. ↩

-

Learn about the common battery-related hassles with cordless tools to understand the advantages of corded devices better. ↩

-

Understanding shock risks can help prevent accidents and ensure safety when using electrical cords. ↩

-

Knowing the correct amperage draw is crucial for selecting the right extension cord and preventing overheating. ↩