What Is Impact Test?

Have you ever wondered how electrical products handle drops, collisions, or unexpected physical stress? The impact test answers these questions by evaluating a product’s durability under mechanical forces.

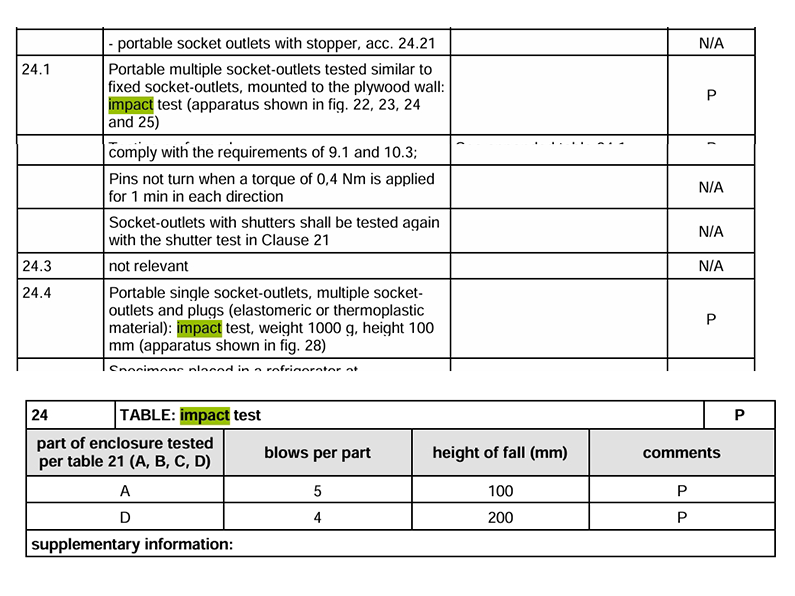

An impact test measures a product’s ability to withstand sudden force or stress without breaking, cracking, or losing functionality. It ensures materials meet safety and durability standards like IEC 60884-1, guaranteeing performance in real-world conditions.

Let’s break down what impact testing means and why it’s essential, especially for products like power strips.

What Does Impact Tested Mean?

When a product claims to be "impact tested," what does that really mean?

Impact tested means the product has undergone controlled evaluations to assess its strength and durability when subjected to sudden force or mechanical shock. This ensures it can endure real-life stress without compromising safety or performance.

How Impact Testing Ensures Reliability

Impact testing involves dropping, striking, or applying force to a product’s surface or components under specific conditions. The results reveal whether the product maintains its integrity and functionality, especially in scenarios like accidental drops or collisions during use.

For example, a power strip tested under IEC 60884-1 must withstand impact forces without cracks or internal damage, ensuring continued safe operation even after physical stress.

What Is the Impact Performance Test?

Impact performance tests sound technical, but they are straightforward in purpose.

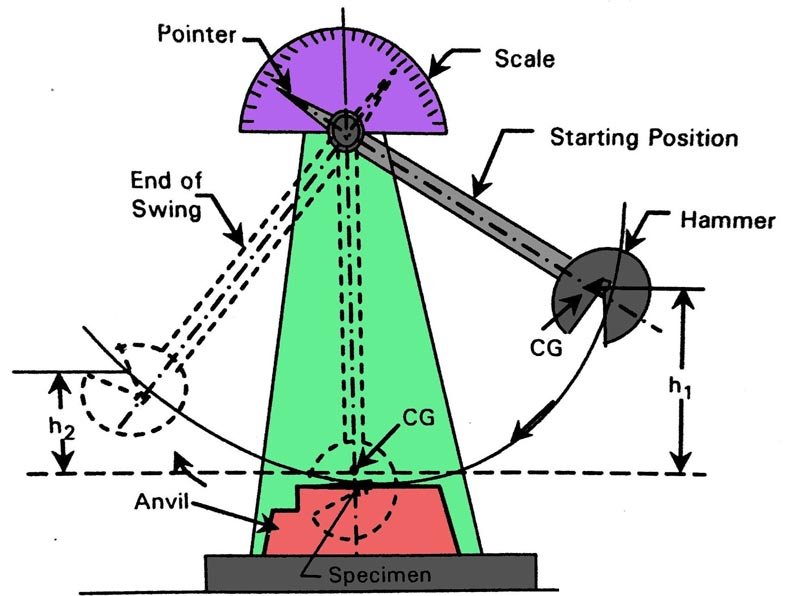

The impact performance test evaluates how well a material or product can resist damage under sudden mechanical forces. It helps manufacturers assess whether products meet durability standards and maintain safety during normal usage and mishandling.

How the Impact Performance Test Works

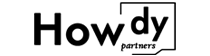

The test involves applying force to the product using calibrated equipment. Key factors include:

- Force Measurement: Determines the amount of energy the product can absorb before failing.

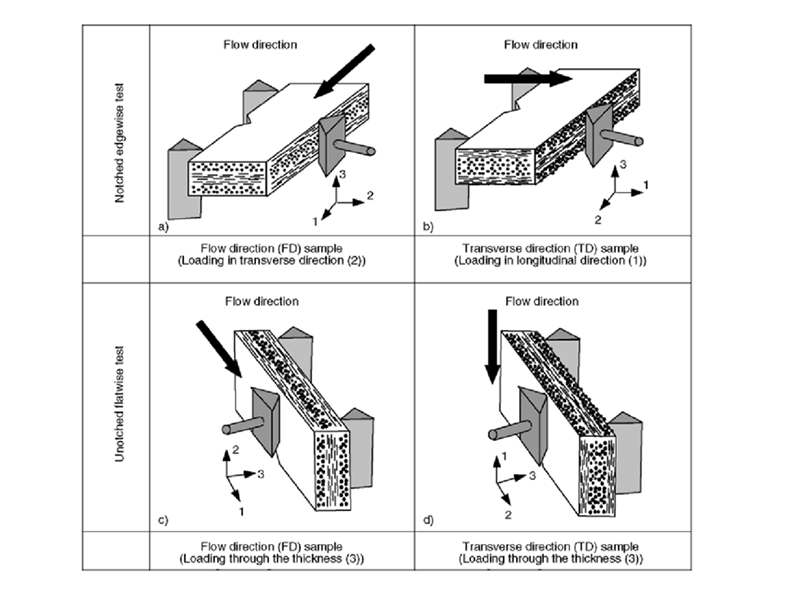

- Material Response: Observes whether the product cracks, deforms, or maintains its integrity.

- Repeatability: Ensures consistent results across multiple samples.

For power strips, these tests are critical. They simulate scenarios like accidental drops from a desk or pressure from heavy objects, ensuring the casing, sockets, and internal wiring remain intact.

| Test Parameter | Importance |

|---|---|

| Force Application | Simulates real-world stress conditions |

| Damage Observation | Identifies weak points in material |

| Compliance Validation | Confirms adherence to IEC standards |

What Is the Most Common Impact Test?

Impact testing comes in many forms, but which one is used most frequently?

The most common impact test is the drop test, where a product is dropped from a specific height to assess its ability to withstand impact. This test evaluates durability and structural integrity, making it a staple in quality control.

Exploring the Drop Test

The drop test is simple yet effective. It involves:

- Setting the Drop Height: Based on product specifications and usage scenarios.

- Releasing the Product: Dropped onto a hard surface like concrete or steel.

- Analyzing the Outcome: Inspections determine whether the product suffers functional or cosmetic damage.

This test aligns with international standards like IEC 60068-2-31 for environmental testing. For power strips, it verifies that casings won’t crack, sockets won’t dislodge, and internal components remain operational even after accidental drops.

What Is the Impact Test for Power Strips?

Power strips often endure tough conditions, but how are they tested for durability?

The impact test for power strips evaluates their resistance to mechanical stress, such as drops, collisions, or pressure. It ensures the strip’s housing, sockets, and internal wiring remain intact and functional, meeting safety standards like IEC 60884-1.

How Power Strips Are Tested for Impact

- Preparation: Power strips are placed in testing rigs designed to simulate real-world mechanical stress.

- Impact Application: Dropping, striking, or compressing tests are conducted using calibrated equipment.

- Assessment: The strip is inspected for cracks, socket dislodgement, or wiring damage.

For manufacturers like Howdy, these tests ensure our power strips meet the high standards expected by clients in Germany, France, and beyond. Passing impact tests demonstrates that the products can withstand everyday challenges, whether in a busy office or a DIY workshop.

| Impact Test Criteria | Power Strip Safety Goals |

|---|---|

| Drop Resistance | Prevents casing cracks or damage |

| Structural Integrity | Ensures sockets remain secure |

| Internal Component Safety | Protects against short circuits |

Conclusion

Impact testing is a vital part of product development, ensuring that electrical devices like power strips remain durable and reliable under real-world conditions. By adhering to standards like IEC 60884-1, manufacturers create products that can handle the unexpected, providing peace of mind for users everywhere.