What is Glow Wire Testing?

Glow wire testing might sound like a niche technical term, but it’s a critical safety measure for electrical products. It ensures materials can handle extreme heat and resist fire, safeguarding the devices we rely on daily.

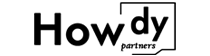

Glow wire testing involves applying a heated metal wire to a product’s surface to simulate the effects of electrical overheating. This test evaluates whether the material ignites, self-extinguishes, or drips flaming particles. It’s a requirement under standards like IEC 60695-2-10 to ensure compliance with fire safety protocols.

Let’s uncover how glow wire testing works and why it’s essential for modern electrical safety.

What is the Difference Between a Glow Wire Test and a Needle Flame Test?

Ever wondered why both glow wire and needle flame tests exist and how they differ?

The glow wire test assesses a material’s resistance to heat from electrical faults by using a heated wire. In contrast, the needle flame test simulates fire risks from small ignition sources like sparks. Both tests aim to ensure fire safety but address different potential hazards.

Comparing Glow Wire and Needle Flame Tests

| Test Type | Method | Purpose |

|---|---|---|

| Glow Wire Test | Heated wire applied to material | Simulates electrical overheating |

| Needle Flame Test | Small flame applied to material | Simulates ignition from sparks |

| Focus | Internal heat generation risks | External ignition source risks |

| Standards | IEC 60695-2-10 | IEC 60695-2-2 |

By combining these tests, manufacturers ensure their products meet comprehensive safety standards, offering better protection against various fire hazards.

What is Needle Flame Test?

Curious about how the needle flame test works and why it’s so significant?

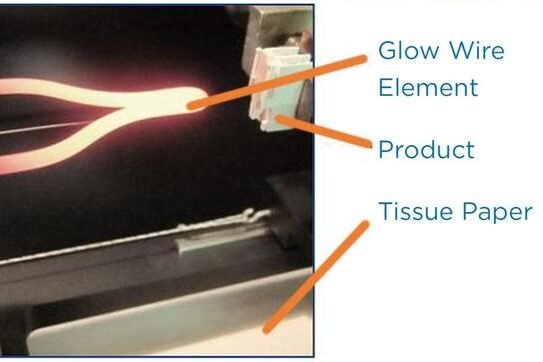

The needle flame test involves applying a small, controlled flame to a material to evaluate its fire resistance. It ensures that products don’t easily ignite or spread flames, making it a crucial part of safety testing for electrical components.

How the Needle Flame Test Protects You

During the needle flame test, a fine flame from a needle-shaped burner is applied to the product. This simulates real-world risks like sparks or small ignition sources. Materials that resist ignition or self-extinguish within set time limits pass the test, proving their reliability under fire hazard conditions.

For manufacturers like Howdy, implementing this test ensures compliance with IEC 60695-2-2 and builds trust with clients, especially in markets like Europe where fire safety standards are stringent. The test’s results directly influence material selection and product design to enhance user safety.

What is the IEC Standard for Glow Wire Test?

Wondering which international standard governs glow wire testing?

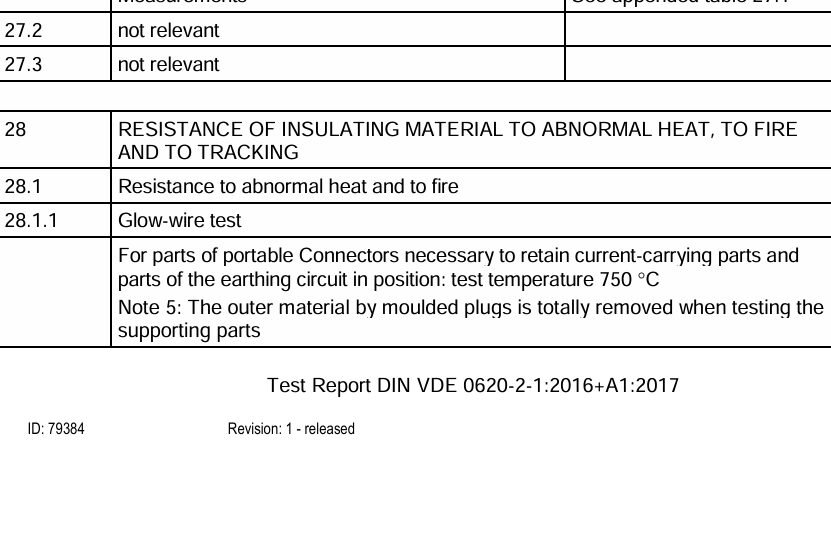

The glow wire test is defined by IEC 60695-2-10. This standard outlines the procedure for assessing materials’ resistance to heat and fire caused by electrical faults, ensuring products meet global safety requirements.

Breaking Down IEC 60695-2-10

IEC 60695-2-10 provides a structured methodology for conducting glow wire tests. Key aspects include:

- Test Temperature: The wire is heated to a specific temperature (e.g., 550°C, 750°C, or 850°C) based on the product’s intended use.

- Material Assessment: The test evaluates ignition time, flame self-extinguishment, and dripping behavior.

- Pass/Fail Criteria: Materials must self-extinguish quickly and avoid producing flaming droplets.

This standard is critical for ensuring consistency and reliability in fire safety evaluations. For products like power strips, compliance with IEC 60695-2-10 demonstrates a commitment to user protection and product reliability.

What is Glow Wire Testing for Power Strips?

Power strips are indispensable in modern homes and offices, but they also face significant safety challenges. How does glow wire testing ensure their reliability?

Glow wire testing for power strips evaluates the fire resistance of their materials under high heat conditions. By simulating overheating scenarios, this test ensures that power strips meet safety standards like IEC 60695-2-10, reducing fire risks from electrical faults.

The Role of Glow Wire Testing in Power Strip Safety

Power strips often operate in demanding environments, powering multiple devices simultaneously. Overloading or wiring faults can generate extreme heat, making fire resistance a top priority. Glow wire testing ensures that:

- The plastic housing and internal components can withstand high temperatures.

- The product resists ignition and self-extinguishes quickly if exposed to heat.

- No flaming droplets are produced, reducing secondary fire risks.

For manufacturers like Howdy, adhering to glow wire test standards is essential. It not only ensures compliance with IEC 60695-2-10 but also boosts customer confidence in product safety. By meeting these requirements, we create power strips that protect homes, offices, and public spaces from potential fire hazards.

Conclusion

Glow wire testing is more than a technical procedure—it’s a cornerstone of fire safety in electrical products. By ensuring compliance with standards like IEC 60695-2-10, manufacturers safeguard their customers against risks from electrical overheating. From power strips to everyday appliances, this critical test ensures reliability, safety, and peace of mind.