Custom OEM Power Strips: Branding Opportunities for Global Retailers

When power strips move from “generic utility” to a branded touchpoint, own-label (OEM)1 becomes a powerful lever for global retailers to grow margin, stand out on the shelf, and stabilise supply. This practical guide shows why to do OEM, what to customise, and how to pick the right factory partner.

Why OEM Power Strips Are a Strategic Choice for Global Retailers

- Margin & category control — Shift from open-market SKUs to private label to improve margin and steer pricing, replenishment, and assortment.

- Visible differentiation — Socket spacing, USB-C PD power, cord length, flat/angled plug, child shutters, and finishes you can see on the shelf.

- Compliance by design — Build in CE/UKCA, UL/ETL, RoHS, REACH2 from day one to reduce returns and customs friction.

- Long-term brand equity — Stable quality plus dependable fulfilment creates review depth and repeat purchase.

In short: OEM isn’t “slap on a logo”. It’s a joined-up upgrade across brand strategy, engineering compliance, and supply resilience3.

Key Customisation Options: Design, Packaging, and Technical Features

Industrial design & mechanics

- Body: bar / tower / ultra-slim / wall-hugging; flame-retardant housing (e.g., UL94 V-0).

- Sockets: EU / UK / US / multi-standard; wide spacing for chunky plugs; shrouded child-safe shutters.

- Cable: 0.75–1.5 mm² (EU) / 14–16 AWG (US); 1–3 m; flat or right-angle mains plug.

Power & protection

- USB: USB-C PD 30/45/65/100–140 W4 (optionally PPS), with mixed USB-A if needed.

- Safety stack: overload reset5, thermal cut-off, surge protection6 (specify joules), EMI/RFI filtering.

- Efficiency: low standby draw (target <0.5 W).

Smart & software

- Wi-Fi / Matter / Thread; per-outlet control, scheduling, and kWh reporting.

- Scenes and automation (sleep/away), optional local-only modes.

Packaging & compliance

- Recyclable packaging; multilingual EU/UK labels; QR to digital manuals and certificates.

- Market-ready test plans for CE/UKCA, UL/ETL, RoHS/REACH, and (where applicable) eco-design.

Quick selector

| Target User | Primary Value | Suggested Spec |

|---|---|---|

| Home/office hero SKU | Safety + charging | 6 outlets + USB-C 65 W, overload + surge, 1.8 m lead |

| Gaming/AV | High joules + noise filtering | Wide spacing, EMI/RFI, surge ≥ 1000 J |

| Travel | Compact + universal input | Mini 3-outlet + 2×USB-C PD (65 W shared), 100–240 V |

| Smart home | Per-outlet control + energy | App control, schedules, kWh reporting (Matter optional) |

HOWDY Power Strip Factory: OEM Advantages

- 20+ years’ manufacturing in China across power strips, cable reels, extension cords, adapters, plugs & couplings.

- Design + engineering in-house — industrial design, tooling collaboration, and PCBA power planning for USB-C PD 30–140 W.

- Compliance toolkit — proven pathways for CE/UKCA, GS, UL/ETL, RoHS/REACH with prototype testing, corrective actions, and complete documentation (DoC, EN/UL reports).

- Flexible MOQs — start small (pilot lots) and scale; ideal for supermarkets, DIY channels, and e-commerce launches.

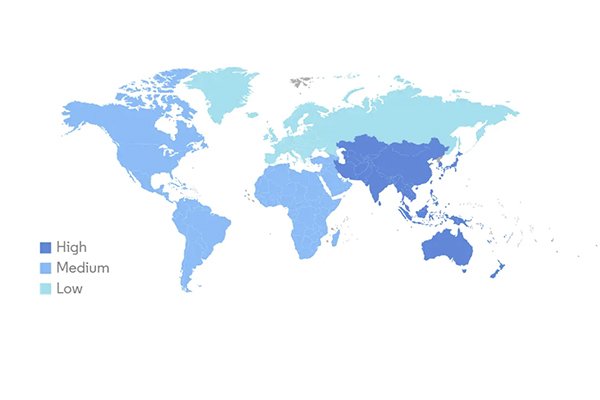

- Global export track record — Germany, France, UK, Spain, Italy, Poland, USA, Australia.

- Delivery discipline — capacity planning, milestone reporting, artwork/packaging co-development, and shelf-ready accessories (brackets, cable clips, POS cards).

- Fast market entry — combine in-stock modules + custom fascia/packaging for a 4–6 week sample-to-shelf sprint, then iterate.

Website: how-dy.com — B2B, wholesale, OEM/ODM enquiries welcome.

How Custom Branding Enhances Market Competitiveness in Power Strips

- Instant recognition — colourways, textures, icons, and status lights that read “your brand” from a metre away.

- Translate tech into benefits — turn “surge joules / overload / USB-C PD / child shutters” into clear iconography and simple, outcome-based copy.

- Own more shelf space — cover needs from “under-desk slim” to “AV wide-spacing” and “travel micro”, capturing multiple price points.

- Close the loop — energy-use dashboards7 and durability improvements feed reviews and create a moat of trust.

Choosing the Right OEM Power Strip Factory for Long-Term Partnerships

Evaluation checklist (hands-on)

- Compliance competence — recent CE/UKCA/UL/ETL cases, third-party reports, and a staged plan for type tests + production sampling.

- Engineering depth — mature BOMs for USB-C PD 65–140 W, PPS, surge/overload/thermal control, and socket spacing/lead optimisation.

- Quality system — traceable IQC/IPQC/OQC with data logs; supports AQL and customer audits.

- Supply resilience — dual-sourcing for GaN, MOVs, copper cable; peak-season capacity; safety stock options.

- Project management — English (and ideally German) comms, weekly updates, sample Gantt, and change control.

- After-sales & traceability — serialisation/QR8, digital manuals, batch recall playbook.

Typical milestones (T-0 to launch)

- T-0: Requirements lock (markets, certifications, look & feel, PD power map).

- T-2–4 wks: ID/ME review, EVT samples, early safety gap check.

- T-5–8 wks: DVT (cert submissions, corrective actions), packaging artwork, POS materials.

- T-9–12 wks: PVT pilot run, line jigs, first mass production + third-party inspection.

- Post-launch: Rolling replenishment, cosmetic refreshes, energy/return analytics.

Conclusion

OEM power strips are a brand strategy + engineering + supply upgrade in one move. Build around certifiable safety (overload, surge, thermal), USB-C PD, low standby power, recyclable packaging9, and optional smart control. With a capable partner such as HOWDY, you can validate quickly at low MOQ, scale confidently, and turn a commodity category into a high-retention, high-margin10 private-label winner.

Want this turned into a spec checklist or a sampling brief template for your team? Tell me your target markets and budget band, and I’ll tailor it.

-

Explore how own-label products can enhance brand identity and profitability for retailers. ↩

-

Understanding these certifications is crucial for compliance and market access in the EU and US. ↩

-

Understand the significance of supply resilience in ensuring consistent product availability. ↩

-

Learn about the benefits of USB-C PD technology for efficient charging solutions. ↩

-

Discover the safety features that protect devices from overloads in power strips. ↩

-

Find out how surge protection can safeguard your electronics from power spikes. ↩

-

Learn how energy-use dashboards can help consumers monitor and manage their energy consumption. ↩

-

Discover how serialisation and QR codes enhance product traceability and consumer trust. ↩

-

Explore the environmental advantages and consumer appeal of recyclable packaging. ↩

-

Learn about strategies that can transform standard products into high-margin, high-retention offerings. ↩