Needle Flame Test for Power Strips

The needle flame test is a critical safety test used to assess the flammability of materials used in electrical devices, including power strips. This test ensures that the insulating and structural materials of the power strip can resist catching fire or limit flame propagation if exposed to a small ignition source. The needle flame test is essential for ensuring that power strips meet international safety standards and are suitable for use in both household and industrial environments.

Purpose of the Needle Flame Test

The needle flame test is designed to evaluate how well the materials of a power strip can withstand direct exposure to a small flame. This test helps verify that the product will not easily ignite and, if it does catch fire, that it will self-extinguish or not allow flames to spread. The primary objective of the test is to prevent the power strip from contributing to larger fires if a fault occurs.

This test is crucial because:

- It reduces the risk of fire in case of electrical malfunctions.

- It ensures compliance with safety standards, such as IEC 60695-11-5.

- It provides safety assurance for consumers, especially in environments where multiple devices are connected.

Test Procedure

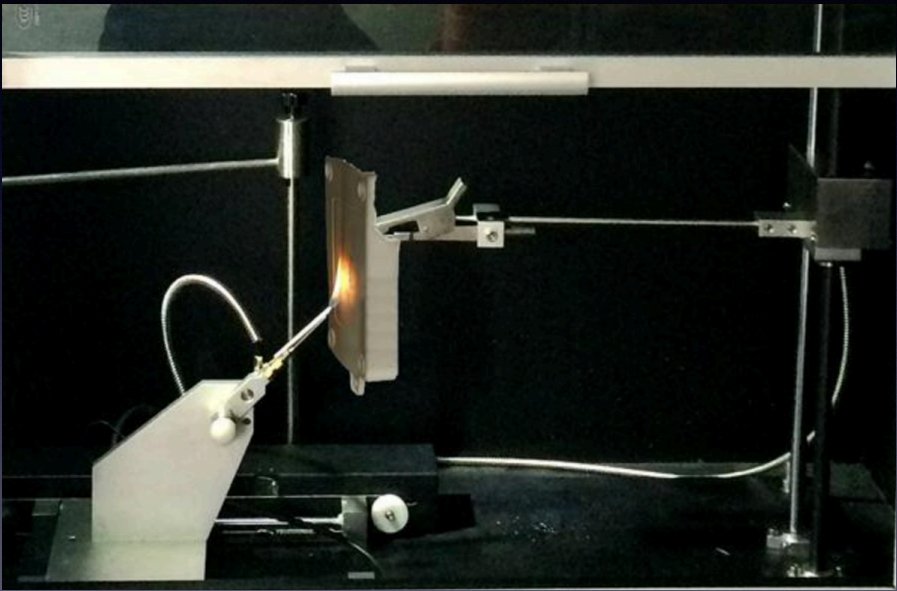

The needle flame test follows the procedure outlined in IEC 60695-11-5, which defines the flammability test method for electrical products. The test replicates what might happen if a small flame were to come into contact with the insulating material or any other plastic component of the power strip.

Key Steps in the Needle Flame Test Procedure:

-

Preparation:

- A needle flame burner is used to produce a flame of 12mm in length. The flame is applied to the material for a specific duration.

- The power strip, or a sample of the material used in its construction, is mounted vertically. The area being tested typically includes insulating plastic or structural components that could be exposed to heat or fire.

-

Flame Application:

- The flame is applied to the material at an angle of 45 degrees for a duration of 10 seconds.

- After 10 seconds of flame exposure, the burner is removed, and the material is observed to see whether it ignites and, if so, how long it continues to burn.

-

Observations:

- The key observation is whether the material self-extinguishes after the flame is removed.

- Any dripping of flaming material is also noted, as this could cause fire to spread.

- A piece of tissue paper or a small pad is placed beneath the sample to check whether the power strip’s material allows flaming droplets to fall, which could ignite a secondary surface.

-

Pass/Fail Criteria:

- The material must self-extinguish within 30 seconds after the flame is removed.

- No flaming drips should ignite the tissue paper placed below the sample.

- The material should show minimal afterglow or smoldering after the test.

Testing Conditions:

- The flame temperature is typically around 850°C, which simulates conditions that could arise from an electrical fault, such as a short circuit.

- The test is performed in a controlled environment, free from drafts and with proper ventilation to ensure accurate results.

Importance of the Needle Flame Test for Power Strips

Power strips are widely used to connect multiple electrical devices, and any malfunction could lead to overheating or even a fire. Therefore, the needle flame test is crucial for verifying the safety of the materials used in power strips. By testing their resistance to small flames, manufacturers can ensure that:

- Fire Risks are Minimized: The materials will not ignite easily or contribute to the spread of fire in the event of an electrical failure.

- Compliance with Standards: The needle flame test is a requirement for compliance with CE certification and other international safety standards, such as IEC 60695-11-5.

- Product Safety: Consumers can trust that the power strip will not pose an unnecessary fire risk, even when used in demanding environments.

Materials Commonly Tested

The materials commonly tested in the needle flame test for power strips include:

- Polycarbonate (PC): Known for its heat resistance and flame-retardant properties, polycarbonate is often used in high-end power strips.

- Polypropylene (PP): A more affordable material, polypropylene requires careful testing to ensure it meets fire safety standards.

- PVC (Polyvinyl Chloride): Frequently used for cable insulation and housing, PVC must be flame-resistant to prevent fire hazards in power strips.

Compliance with CE Standards

To comply with CE standards and be certified for sale in the European Economic Area (EEA), power strips must pass the needle flame test in accordance with IEC 60695-11-5. This ensures that the product can safely resist ignition and flame spread, protecting consumers from potential fire hazards. Additionally, passing the needle flame test is often required to meet other global safety standards, such as those set by UL and CSA.

Real-World Applications

The needle flame test is especially important for power strips used in environments where multiple electrical devices are connected simultaneously, such as:

- Offices: Where power strips may be used for computers, printers, and other electronics.

- Workshops and Factories: Where power strips may be exposed to high loads and industrial equipment.

- Homes: Ensuring that power strips can safely handle the needs of household appliances and electronic devices.

Conclusion

The needle flame test is an essential safety measure for power strips, ensuring that their materials can withstand exposure to small flames and prevent fire hazards. By passing this test, power strips comply with CE and other international safety standards, making them safe for use in both residential and industrial environments. The test’s focus on flammability resistance ensures that these devices protect users and property from the dangers of electrical fires.