Shuttered Power Strip: Enhanced Safety for Your Devices

When it comes to power strips, safety is a top priority—especially in environments where accidental contact with live electrical components could occur. One of the most effective safety features integrated into modern power strips is the shutter mechanism. Let’s explore what a shuttered power strip is and how it benefits both consumers and businesses, along with the relevant IEC test standards that ensure their safety and reliability.

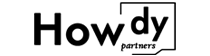

What is a Shuttered Power Strip?

A shuttered power strip is a type of power strip that includes built-in safety shutters within each outlet. These shutters block direct access to the electrical contacts inside the socket, ensuring that only a plug with the correct prongs can enter. The shutters remain closed when the power strip is not in use, offering a protective barrier against accidental exposure to live electrical components.

How Shutters Work

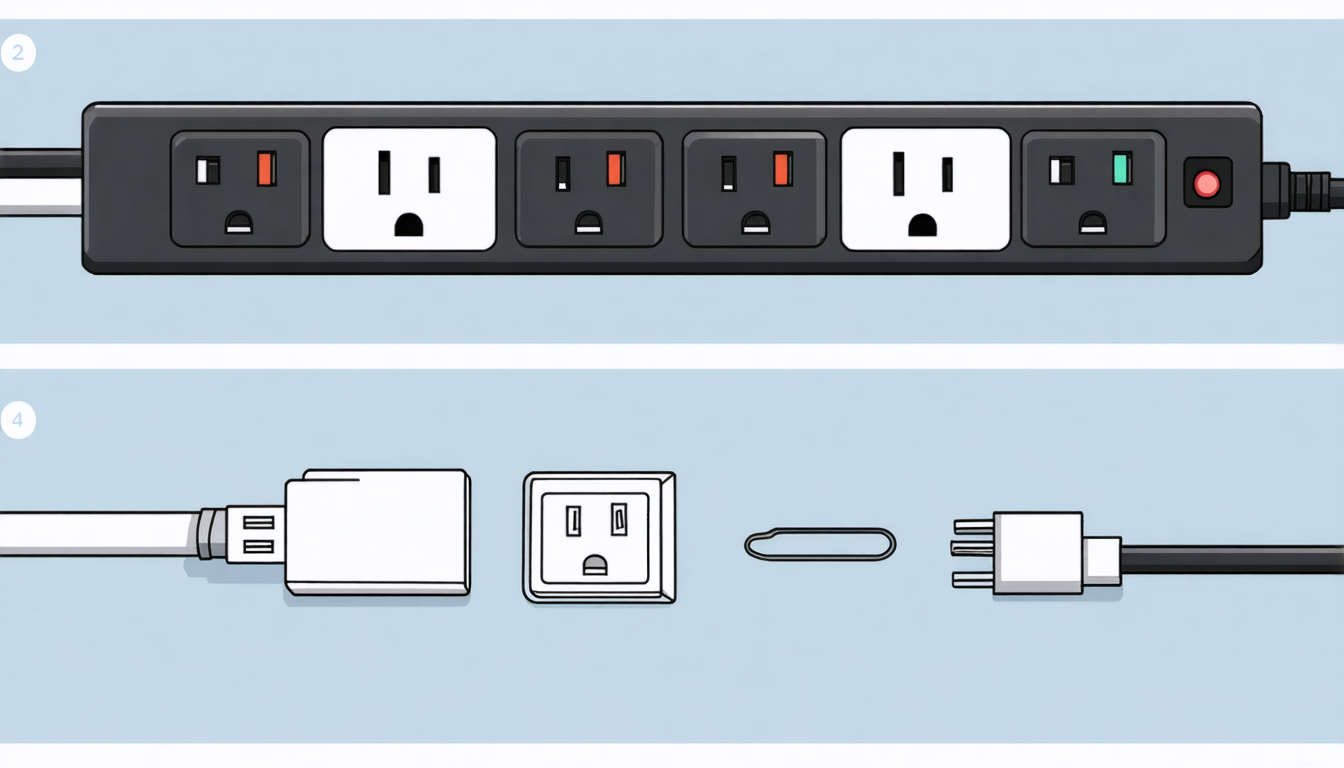

- Blocking Access: The shutters inside each outlet prevent foreign objects from being inserted, which is especially important in environments with children, pets, or high traffic.

- Opening Upon Proper Insertion: When a properly designed plug is inserted into the socket, both prongs push the shutter open simultaneously, allowing the plug to connect to the electrical contacts safely.

- Preventing Accidents: The shutters only open when pressure is applied to both prong slots at the same time. This design prevents items like paper clips, keys, or other foreign objects from being inserted, minimizing the risk of electric shocks or short circuits.

Benefits of Shuttered Power Strips

1. Enhanced Safety

The primary advantage of a shuttered power strip is the significant improvement in safety. By restricting access to live electrical parts, the shutter mechanism helps prevent:

- Electric Shock: Particularly important in homes, schools, or businesses where children might be tempted to insert objects into outlets.

- Short Circuits and Fire Hazards: Blocking foreign objects from reaching the electrical contacts can reduce the risk of sparks, overheating, or electrical fires.

2. Compliance with Safety Standards

Shuttered outlets are now widely required by international safety standards, including those set by the International Electrotechnical Commission (IEC). These standards outline rigorous testing to ensure that shuttered outlets provide adequate protection under various conditions.

IEC Standards for Shuttered Power Strips

-

IEC 60884-1: Plugs and Socket-Outlets for Household and Similar Purposes

- This standard specifies the general requirements for plugs and socket-outlets, including those with shutters. It ensures that the shutter mechanism can resist both accidental access and tampering while allowing easy operation when used with compatible plugs.

- Key Tests:

- Mechanical Strength: Ensures the shutter mechanism withstands regular use without failure.

- Operation Test: Validates that the shutters function correctly under normal insertion and withdrawal forces.

- Endurance Test: Simulates frequent use over time to ensure that the shutters remain operational after a specified number of cycles.

-

IEC 61058-1: Switches for Appliances

- This standard covers switching mechanisms in power strips, ensuring safe disconnection and connection of electrical circuits, particularly in combination with shuttered outlets.

- Key Tests:

- Electrical Endurance: Ensures the switch can operate safely after a defined number of switching cycles.

- Temperature Resistance: Verifies that the switch and shutters maintain function under extreme temperatures.

-

IEC 60364: Low-Voltage Electrical Installations

- This standard provides guidelines for safe installation and use of low-voltage electrical systems, including power strips with shuttered outlets.

- Key Tests:

- Protection Against Electrical Shock: Ensures that the shutter system is sufficient to prevent accidental access to live parts.

- Impact Resistance: Tests the ability of the shutters to resist impact from external forces, protecting the internal electrical contacts.

3. Ideal for Commercial and Industrial Use

For workplaces that handle electrical equipment, shuttered power strips offer additional safety during operations:

- Industrial and Workshop Environments: Where tools and metal objects are often handled, the risk of inserting foreign objects into live sockets is higher. Shuttered power strips protect employees and equipment.

- Office Spaces: Reduces the chance of accidents, especially in offices with multiple users, ensuring compliance with workplace safety regulations.

4. Durability and Reliability

Shutter mechanisms are designed to withstand frequent use without compromising safety. Many shuttered power strips are built from durable materials that ensure long-term reliability even in heavy-use environments like factories or workshops.

When Should You Use a Shuttered Power Strip?

Shuttered power strips are ideal in situations where additional safety measures are required. Consider using shuttered power strips in the following environments:

- Homes with Children: To protect curious children from accidentally accessing electrical sockets.

- Public Spaces: In hotels, libraries, schools, or any place where multiple users have access to power outlets.

- Workshops and Industrial Settings: To prevent foreign objects from entering sockets during day-to-day operations, reducing risks in environments with heavy tools and equipment.

- Offices and Commercial Spaces: For compliance with safety standards and to offer protection in shared spaces.

Conclusion

A shuttered power strip provides enhanced protection by incorporating a simple yet effective mechanism that prevents accidental access to live electrical components. Whether you’re looking to improve safety at home, in a workshop, or in a commercial environment, shuttered power strips offer peace of mind and compliance with modern safety standards. Tested and certified under IEC 60884-1, IEC 61058-1, and IEC 60364, shuttered power strips meet the highest levels of safety and durability.