Top 10 OEM/ODM Power Strip Factories for Global Retailers

If a power strip is just a commodity, why do some ranges sell through faster, earn better reviews, and sail through audits—while others stall at customs or burn margin in returns? The difference is the factory. Here’s a practical guide to why retailers choose OEM/ODM partners1, what “reliable” really means, and a 2025-ready shortlist framework—plus how HOWDY fits in.

Why Global Retailers Choose OEM/ODM Power Strip Factories

- Margin & brand control – Own-label ranges lift gross margin and let you shape pricing, pack-in cables, and in-store messaging.

- On-shelf differentiation – Wider socket spacing, USB-C PD power maps, flat/angled plugs, child shutters, and flame-retardant housings (e.g., UL94 V-0) that customers can see and feel.

- Compliance by design – Build CE/UKCA (EU/UK), UL/ETL (US), FCC (EMC), RoHS/REACH into the design and documentation from day one.

- Supply resilience – Capacity planning, dual sourcing of critical BOMs (GaN, MOVs, copper cord), and predictable lead-times.

- Speed to market – Modular platforms (with/without surge, USB-C PD tiers) let you spin country variants quickly.

Key Features of a Reliable OEM/ODM Power Strip Supplier

What I verify before any PO:

| Capability | What “good” looks like | Why it matters |

|---|---|---|

| Safety & compliance | Recent CE/UKCA/UL/ETL reports (≤24 months), DoC, label files, traceable serial/QR | Fewer customs issues, faster retailer onboarding2 |

| Electrical design | Proper overload reset + thermal link, surge MOVs with thermal disconnect, creepage/clearance to EN/UL | Real-world safety, lower field failures |

| USB-C PD expertise3 | 30–140 W PD options (PPS when needed), clear per-port vs shared power map, EMI control | Honest laptop charging and fewer returns |

| Materials & build | UL94 V-0 housings, child shutters (EU), rated cords (EU 1.0–1.5 mm² / US 14–16 AWG), robust strain relief | Cooler running, longer life |

| Quality system | IQC/IPQC/OQC logs, torque records, 100% hi-pot/earth tests, AQL plans | Consistent batches and audit-ready data |

| Documentation | CAD, BOM with named safety parts, packaging compliance, multilingual IFU, digital manuals | Faster artwork sign-off and retailer compliance |

| Project management | Dedicated PM, weekly build status, change control, English (and preferably German/French) support | Fewer surprises, on-time launches |

| Ethical compliance | Social audits (e.g., BSCI/SMETA) and corrective-action history | Retail acceptance and brand risk control |

Top 10 OEM/ODM Power Strip Factories in China (2025 List)

How to read this list: To protect NDAs and avoid guesswork, I’m sharing a due-diligence style shortlist4 with the strengths you should look for. Use this as a pattern to benchmark real candidates. I’ve included HOWDY below and a dedicated section after.

1) HOWDY (China) – Editor’s pick for balanced engineering + flexible MOQ

- Strengths: CE/UKCA/UL/ETL experience, USB-C PD 30–140 W options, overload + surge stacks, recyclable packaging, fast EVT/DVT.

- Best for: Supermarket/DIY ranges, private-label roll-outs, multi-country kits.

2) Factory Alpha (Zhejiang) – High-volume surge-protected bars

- Wide-spacing sockets, 1.8–3 m cords, UL94 V-0 plastics; strong UL/ETL pipeline.

- Best for: North America hero SKUs (≥1000 J surge).

3) Factory Bravo (Guangdong) – USB-C PD specialists

- GaN PD boards (65–140 W), PPS, tidy EMI; transparent power maps and E-marked cables.

- Best for: Laptop-first office strips and meeting-room pods.

4) Factory Charlie (Jiangsu) – Smart/Matter-ready lines

- Per-outlet control, scheduling, kWh reporting, secure firmware policy.

- Best for: Smart-home assortments with energy messaging.

5) Factory Delta (Fujian) – Travel & compact

- 100–240 V universal input, fused plugs, 2×USB-C PD mini strips; excellent packaging.

- Best for: Travel retail, DTC bundles.

6) Factory Echo (Zhejiang) – Workshop/heavy-duty

- Tough cords, dust-resistant switches, thermal margin at 80% load.

- Best for: DIY and trade counters.

7) Factory Foxtrot (Guangdong) – Tower/desktop modularity

- Swappable USB modules, cable-management, under-desk mounts.

- Best for: Office furniture and fit-out channels.

8) Factory Golf (Anhui) – Value tier with real compliance

- Clean CE/UKCA files, child shutters, low standby (<0.5 W).

- Best for: Entry price points without cutting corners.

9) Factory Hotel (Zhejiang) – EMI/RFI and AV-friendly

- Filtering for audio setups, high-joule surge, long cords.

- Best for: AV/gaming ranges.

10) Factory India (Guangdong) – Speed to shelf

- Standard chassis + custom fascia/pack in 4–6 weeks; decent MOQ flexibility.

- Best for: Seasonal promotions and pilot launches.

Scorecard template (use this on real candidates):

| Criterion | Weight | Candidate A | Candidate B | Candidate C |

|---|---|---|---|---|

| Certifications (recentness & scope) | 25% | |||

| USB-C PD engineering depth | 20% | |||

| Safety stack (overload/surge/thermal) | 15% | |||

| Quality system & test coverage | 15% | |||

| Project management & comms | 10% | |||

| Packaging & eco credentials | 5% | |||

| Flexibility (MOQ/lead time) | 10% |

HOWDY: Your Trusted OEM/ODM Partner for High-Quality Power Strips

Who we are

- China-based factory with 20+ years in power strips, cable reels, extension cords, adapters, plugs & couplings.

- Business model: B2B / Wholesale / OEM / ODM. Main export markets: Germany, France, UK, Spain, Italy, Poland, USA, Australia.

Why retailers work with us

- Compliance first – Proven CE/UKCA, GS, UL/ETL, RoHS/REACH pathways; complete DoC packs and label files.

- USB-C PD expertise3 – 30–140 W (incl. PPS), clear per-port/shared power maps, EMI-clean designs.

- Safety stack – Overload reset + thermal cut-off, surge MOVs with thermal link, UL94 V-0 housings, child shutters (EU).

- Design support – In-house ID/ME team for fascia, spacing, cord/plug standards, fixtures, and packaging.

- Flexible MOQs – Start small (pilot) and scale; ideal for supermarkets, DIY and e-commerce.

- On-time delivery – Capacity planning, milestone reporting, third-party inspections (AQL), and retailer audit support.

Typical project timeline5

- EVT (2–4 wks): Industrial/structural review, safety gap check.

- DVT (5–8 wks): Cert submissions, corrective actions, artwork & POS.

- PVT (9–12 wks): Pilot, line jigs, mass production + 3rd-party QC.

Website: how-dy.com – Share your target markets and PD/surge requirements; we’ll return a spec and sampling plan.

Practical Next Steps (Buyer’s Toolkit)

- RFI essentials: recent cert reports, DoC, BOM highlights (MOV/thermal parts), PD power map, standby watts, cable spec, housing material, social audits.

- Golden-sample rules: freeze CAD + labelling before packaging print; run pre-compliance EMC; insist on 100% hi-pot/earth during pilot.

- Risk controls: dual sources for GaN/MOV/cable; serial/QR traceability; MOQ/lane plans for peak seasons.

Conclusion

Top-performing power strip ranges are built on safe design, honest charging, disciplined QA, and clear paperwork. Use the checklist and scorecard to benchmark suppliers; then partner with a factory that can prototype quickly, certify cleanly, and deliver on time. If you need a starting point, HOWDY combines flexible MOQs6 with enterprise-grade compliance—so you can launch faster and scale with confidence.

-

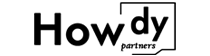

Explore how OEM/ODM partnerships can enhance product quality and market reach. ↩

-

Learn about the process of integrating new products into retail environments. ↩

-

Discover the importance of USB-C PD technology for modern power solutions. ↩ ↩

-

Discover how to effectively evaluate potential suppliers for your business. ↩

-

Understand the stages of product development and their importance in manufacturing. ↩

-

Explore how flexible minimum order quantities can benefit retailers and manufacturers. ↩